Our mission

Anticipate the technical evolutions

and constantly optimize

our customer service

Our vision

Customer expectations always

republished in terms of quality,

responsiveness and delays

Our Industrial Solutions

Three approaches to solve your industrial needs

Speedshop services

serial manufacturing services

mro services

Reception

Feasibility study

- Reservation of the means of production

- Machines

- Human / Workers

- Component stock control

- Raw materials

- Hardware store

Industrialization Manufacturing Production

To respect our prices and deadlines commitments :

- Simplified manufacturing processes

- Standardization of production tools

- Verticalization of industrial process :

Quality Control

To meet the quality promise :

- 100 % of the parts will be checked, without sampling

Expedition

To ensure that the delivery of your parts meets your deadline expectations :

- Internal vehicle fleet

- International logistics partners

- Internalized customs clearance capabilities

- Creation of quality discharge documentation

- FAI

- EASA Form 1

Certification

A positive customer feedback carried by a promise held in quality, deadlines and customer service !

Our References

- AIRBUS

- FAL Support

- Flight Test

- Program Development

- STELIA

- LATECOERE

- SAFRAN

- KOPTER

- SATAIR

KPIs*

- R1: 100%

- D1: 100%

*Data collected and validated by all our customers.

Validation

Once the solution is validated, our commitment :

- Delivery in time of the parts

- 100 % Quality

- A contractualized price

+ Real-time monitoring of your parts

UrgentIndustrialization

Manufacturing

ProductionQuality

ControlExpeditionPiece

receptionCertificationValidation

Speedshop

services

With more than 40 years of experience in the manufacture of aerospace components and sub-systems, the ROSSI AERO Group combines historical expertise with the latest technologies of the aerospace industry. Carried by an emblematic promise of quality, customer service and operational excellence an AOG team will satisfy your needs 24/7.

tracking

Subcontractor

A controlled supply-chain to insure the ROSSI AERO GROUP promise Quality — Reactivity – Time

- External industrial Capacities

Industrial partnership

Industrial partners with complementary expertise to meet all your needs

-

- Example of partnership created for an aircraft manufacturer customer

Small Bed Fabrication

|

Large Bed Fabrication

|

Quality Control Lab

A control laboratory to optimize the flow insuring the quality of all your parts

- Quality control by sampling, studied on an individual basis for each reference.

- Development of new control solutions specific to certain customer’s needs :

- Example : Pressure test bench for Airbus

Logistics Hub

A logistic platform with international delivery capabilities

- Internal vehicles fleet

- International logistics partners

- Internalized customs clearance capabilities

Industrialization production

Optimized Industrialization and production process to reduce costs

- Optimized Industrialisation for the reduction of the “ Recurring Costs” :

- Design 2 cost

- Buy to fly : panoply

- The Serial production plant is designed around the FMS model (Flexible manufacturing system)

- Extra production capacity with our industrial partners

Customer dedicated storage

Possibility to dedicate a plant for the specific storage of parts and tools for certain customers

- Example : Storage plant for certain tools of one of our aircraft manufacturer customers

Raw material storage

A stock of raw materials on a plant used to optimize the flow

- Panels of Materials

- Internal output capacity

- 2000 m2 of stock in house

suppliers

Access to a sample of chosen and inspected suppliers

- The Price and Deadline Guaranty of the ROSSI AERO GROUP is insured by a reliable supply-chain

- Wide array Raw material and hardware suppliers

customer

partnershipQuality

Control LabLogistics HubIndustrialization

productionCustomer dedicated

storageRaw material

storagesupplierscustomer

Serial

Manufacturing

Services

With a 10 000m2 factory dedicated to the production in small and medium series, the ROSSI AERO Group has the best technological resources to meet your expectations. Our industrial maturity was recognized by Airbus as a result of the IPCA+ audit where our mass production plant was Noted with an A.

Reception

For optimized repair times :

- Removal and delivery of your parts directly to our premises.

CND verification of the part

Feasibility study for a solution adapted to your part

- Variety of non-destructive control solutions to offer the best repair option

- Radio control

- Three-dimensional control

- Dye penetrate testing

- Allocation of means

- Human

- Materials

Maintenance Operation P145

For repair operations respecting your TAT :

- Repair process Internalisation :

- Machining

- Boiler making

- SHEET-metal

- Painting

- Surface treatment

- Welding

Quality Control

To guaranty your parts navigability :

- 100 % of your parts will be controlled, without sampling

expedition

To optimize your Turn Around Time :

- Internal vehicle fleet

- International logistics partners

- Internalized clearance capabilities

- Creation of quality discharge documentation :

- EASA/FAA/JAA/ form 1

Manufacture of a new part 21G

In case of an irreparable part

- In-house possibility to produce a new qualified part 21G.

- Start up again of the activity in same time as for a reparation

of the partMaintenance

Operation

P145Quality

ControlexpeditionManufacture

of a new part 21G

MRO

services

The MRO (maintenance, repairs & operations) activity is carried out by the ROSSI MRO SOLUTIONS subsidiary. The launch of this subsidiary is justified by the deadlines and quality requirements of the MRO with a team and production resources available 24/7.

For more information : www.rossi-mro-solutions.com

Request

Recovery

Our Industrial Solutions

Three approaches to solve

your industrial needs

Speedshop services

serial manufacturing services

mro services

Speedshop services

With more than 40 years of experience in the manufacture of aerospace components and sub-systems, the ROSSI AERO Group combines historical expertise with the latest technologies of the aerospace industry. Carried by an emblematic promise of quality, customer service and operational excellence an AOG team will satisfy your needs 24/7.

Reception

Feasibility study

- Reservation of the means of production

- Machines

- Human / Workers

- Component stock control

- Raw materials

- Hardware store

Industrialization Manufacturing Production

To respect our prices and deadlines commitments :

- Simplified manufacturing processes

- Standardization of production tools

- Verticalization of industrial process :

Quality Control

To meet the quality promise :

- 100 % of the parts will be checked, without sampling

Expedition

To ensure that the delivery of your parts meets your deadline expectations :

- Internal vehicle fleet

- International logistics partners

- Internalized customs clearance capabilities

- Creation of quality discharge documentation

- FAI

- EASA Form 1

Certification

A positive customer feedback carried by a promise held in quality, deadlines and customer service !

Our References

- AIRBUS

- FAL Support

- Flight Test

- Program Development

- STELIA

- LATECOERE

- SAFRAN

- KOPTER

- SATAIR

KPIs*

- R1: 100%

- D1: 100%

*Data collected and validated by all our customers.

Validation

Once the solution is validated, our commitment :

- Delivery in time of the parts

- 100 % Quality

- A contractualized price

+ Real-time monitoring of your parts

UrgentIndustrialization

Manufacturing

ProductionQuality

ControlExpeditionPiece

receptionCertificationValidation

tracking

Our industrial solutions

Serial Manufacturing Services

With a 10 000m2 factory dedicated to the production in small and medium series, the ROSSI AERO Group has the best technological resources to meet your expectations. Our industrial maturity was recognized by Airbus as a result of the IPCA+ audit where our mass production plant was Noted with an A.

Subcontractor

A controlled supply-chain to insure the ROSSI AERO GROUP promise Quality — Reactivity – Time

- External industrial Capacities

Industrial partnership

Industrial partners with complementary expertise to meet all your needs

-

- Example of partnership created for an aircraft manufacturer customer

Small Bed Fabrication

|

Large Bed Fabrication

|

Quality Control Lab

A control laboratory to optimize the flow insuring the quality of all your parts

- Quality control by sampling, studied on an individual basis for each reference.

- Development of new control solutions specific to certain customer’s needs :

- Example : Pressure test bench for Airbus

Logistics Hub

A logistic platform with international delivery capabilities

- Internal vehicles fleet

- International logistics partners

- Internalized customs clearance capabilities

Industrialization production

Optimized Industrialization and production process to reduce costs

- Optimized Industrialisation for the reduction of the “ Recurring Costs” :

- Design 2 cost

- Buy to fly : panoply

- The Serial production plant is designed around the FMS model (Flexible manufacturing system)

- Extra production capacity with our industrial partners

Customer dedicated storage

Possibility to dedicate a plant for the specific storage of parts and tools for certain customers

- Example : Storage plant for certain tools of one of our aircraft manufacturer customers

Raw material storage

A stock of raw materials on a plant used to optimize the flow

- Panels of Materials

- Internal output capacity

- 2000 m2 of stock in house

suppliers

Access to a sample of chosen and inspected suppliers

- The Price and Deadline Guaranty of the ROSSI AERO GROUP is insured by a reliable supply-chain

- Wide array Raw material and hardware suppliers

customer

partnershipQuality

Control LabLogistics HubIndustrialization

productionCustomer dedicated

storageRaw material

storagesupplierscustomer

Our industrial solutions

MRO services

The MRO (maintenance, repairs & operations) activity is carried out by the ROSSI MRO SOLUTIONS subsidiary. The launch of this subsidiary is justified by the deadlines and quality requirements of the MRO with a team and production resources available 24/7.

For more information : www.rossi-mro-solutions.com

Reception

For optimized repair times :

- Removal and delivery of your parts directly to our premises.

CND verification of the part

Feasibility study for a solution adapted to your part

- Variety of non-destructive control solutions to offer the best repair option

- Radio control

- Three-dimensional control

- Dye penetrate testing

- Allocation of means

- Human

- Materials

Maintenance Operation P145

For repair operations respecting your TAT :

- Repair process Internalisation :

- Machining

- Boiler making

- SHEET-metal

- Painting

- Surface treatment

- Welding

Quality Control

To guaranty your parts navigability :

- 100 % of your parts will be controlled, without sampling

expedition

To optimize your Turn Around Time :

- Internal vehicle fleet

- International logistics partners

- Internalized clearance capabilities

- Creation of quality discharge documentation :

- EASA/FAA/JAA/ form 1

Manufacture of a new part 21G

In case of an irreparable part

- In-house possibility to produce a new qualified part 21G.

- Start up again of the activity in same time as for a reparation

of the partMaintenance

Operation

P145Quality

ControlexpeditionManufacture

of a new part 21G

Request

Recovery

Our industrial solutions

Our expertise

Besides a perfect control its supply chain, the ROSSI AERO Group, has a complete professional expertise in-house.

machining

Boilermaking

SHEET- metal

surface

treatment

Quality

assembly

welding

painting

Tooling

Service

machining

With more than 40 years of machining expertise working with

3, 4 & 5 axis numerical control machines, ROSSI AERO Group

handles with great precision all operations of boring,

milling, surfacing or mechanical correction.

The Group’s machine park is controlled by a CAD team capable

of satisfying your needs using any type of customer data (3D, plans, technical drawings…).

Boilermaking

SHEET- metal

Experts in all areas of aeronautical sheet- metal and boilermaking,

ROSSI AERO Group has a strong expertise based on more

than 40 years of experience. We will meet all your expectations,

whether by conventional working methods through our manual

workstations, or by modern automated methods thanks

to our centers of folding, bending, press and laser cutting (2 & 5 axis).

surface

treatment

Equipped with a complete surface treatment line, the ROSSI AERO Group

is able to carry out the main processes of the aeronautical industry :

Alodine, TSA, scouring and passivation. These installationsalso

allow the parts preparation for the other manufacturing processes

(painting, welding, Assembly…). All the ponds of the line are weekly

checked by an external control laboratory, in order to guarantee

an optimal quality response to your expectations.

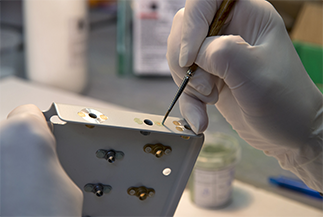

Quality

Being quality control one of the Group’s promises,

investments are constantly being made to maintain

an impeccable level of demand. In addition to having

a control laboratory, the Group offers all conventional control

solutions (manual control, automated control, non- destructive control).

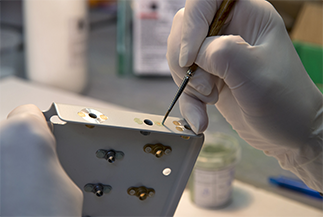

assembly

With proven operational expertise in the Assembly of aeronautical

assemblies and sub-assemblies, the ROSSI AERO Group

meets all your demands on simple and complex mechanical assemblies.

With an in-house surface treatment line your parts will be

put into optimal conditions for efficient mounting.

welding

All the welding facilities of the ROSSI AERO Group

are accredited NADCAP. Expert in both manual and automated welding,

the group is able to satisfy all your requirements on the welding

of the standard Aeronautic materials (Titanium included).

painting

ROSSI AERO Group is qualified in all aeronautical painting processes.

We are able to handle simple or complex parts with a length up to 6 meters.

Being equipped with ovens, the drying times are optimized in order

to deliver your parts on very short deadlines. With an in- house

surface treatment capability your parts will be put under optimal

conditions for a controlled paint application.

Tooling

Service

By internalizing its tooling design and development,

the ROSSI AERO Group acquires a perfect control

of its supply chain and can ensure deliveries of parts

in quality and within extremely short deadlines.

This expertise extends to all production areas (machining,

Assembly, boilermaking, etc.), but also to the control

professions with the creation of certified adapted control tools.